Ø135 Power Chuck

Ø25 Collet Chuck

PHS1036 Rotary Cylinder

for thru Rod cap. Ø25

Ø P50 Rotary Cylinder for

thru Rod cap. Ø18mm

Centralized Lubrication Unit

Flexible Tooling Options

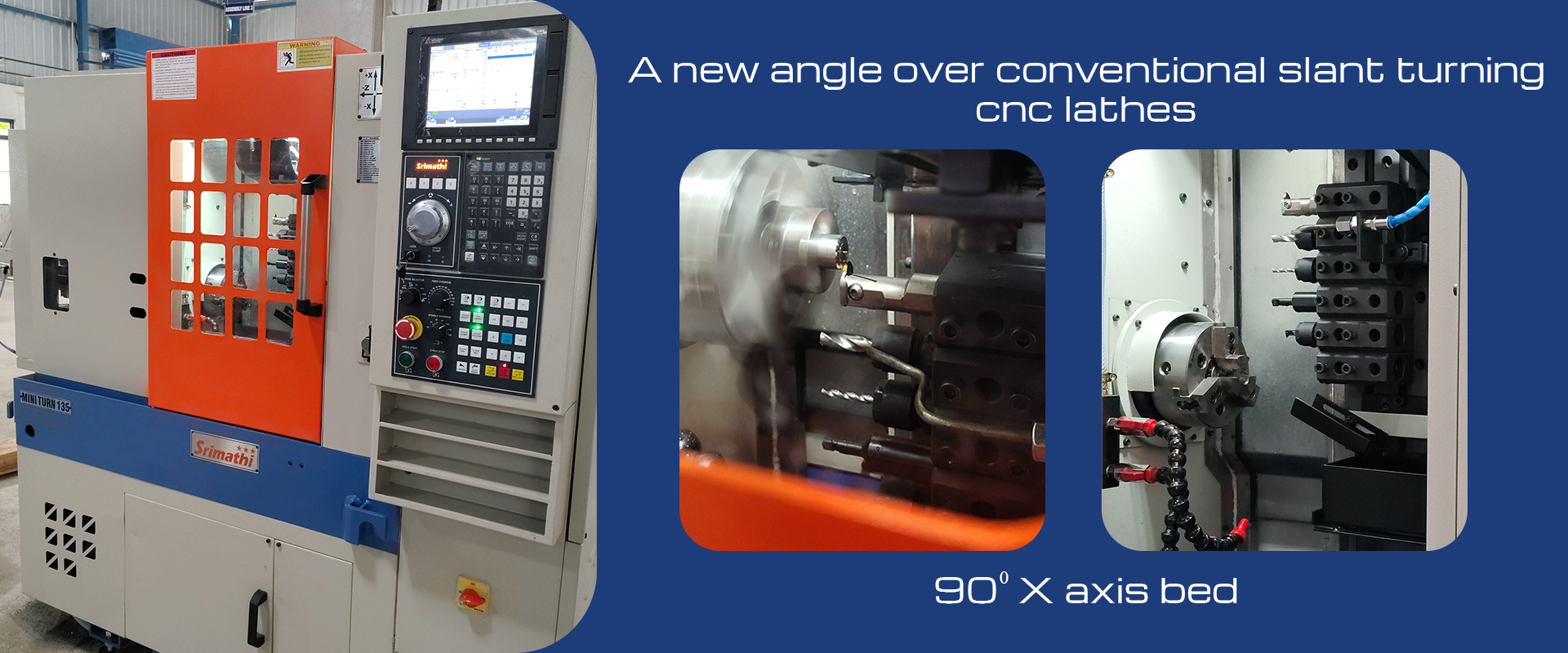

Why Choose our “Mini Turn CNC Turning Lathes” ?

Higher Tools mounts up to 8

due to longer

X axis stroke*

Rigid Structural Design with

Compact foot

print

Quick drain of Burr and

Coolant due to

900 Bed construction

Easy access to Chip Tray and

Coolant Tank

from Machine front side

Bar Feed Attachment

Optimised energy

utilisation

Low maintenance cost

Convenient reach of Spindle

from door

front for secondary operation parts

| CONTENT | UNIT |

|---|---|

| CAPACITY | |

| Bed | 90° Vertical |

| Swing Over Bed | 80 mm |

| Max Turning Dia. thru Bar | 25 mm |

| Max Turning Length | 55 mm |

| Chucking Type | Ø135 Chuck, Dead Length A25 & 5C |

| Clamping thru | Hydraulic Rotary Cylinder |

| MAIN SPINDLE | |

| Spindle Power | 2.2/3.7 Kw Servo (Analog Optional) |

| Spindle Speed (Variable) | 3800 RPM max |

| Front Bearing Bore | Ø65 mm |

| Rear Bearing Bore | Ø55 mm |

| Bore thru Draw Bar | Ø26 mm |

| MACHINE PARAMETER | |

| Total Machine Power | 5 Kw |

| Overall Size (LxBxH) | 1500x800x1800 |

| Overall Weight apprx. | 1850 Kg |

| CONTENT | UNIT |

|---|---|

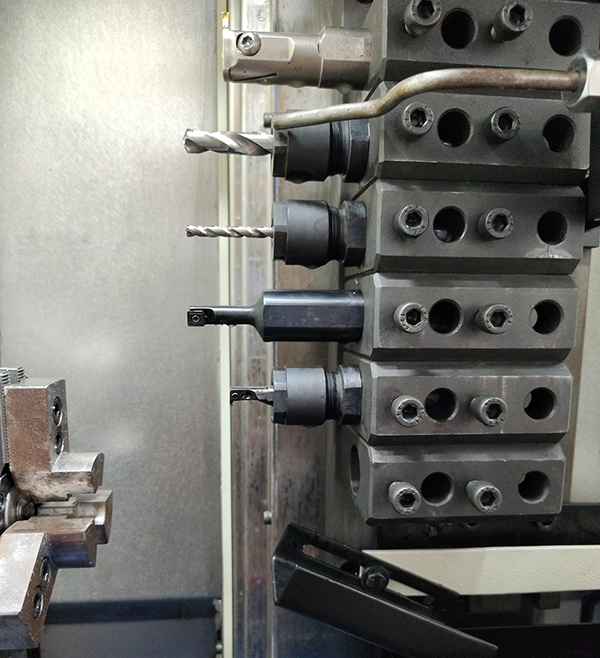

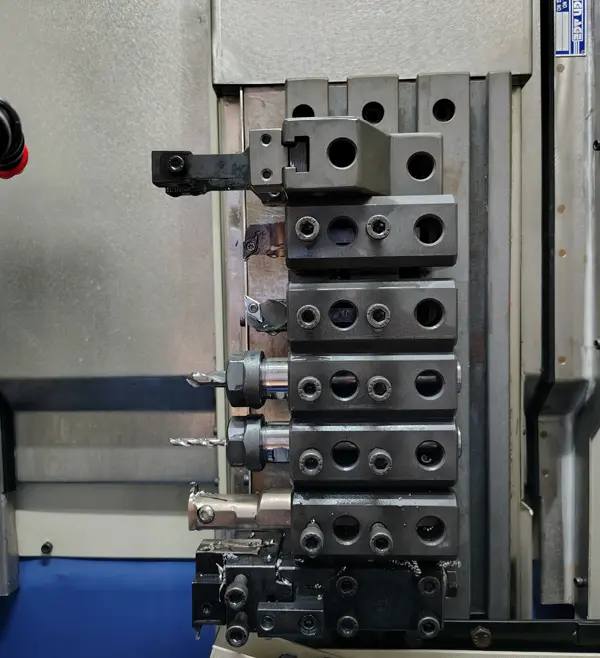

| TOOLING | |

| Type | Gang Tool |

| Model | STD/Customize |

| No. of Tool Positions | Upto 8 |

| Tool Shank Size | Sq.20 |

| Max Boring Bar Dia | Ø20 mm & Ø25 mm |

| ACCURACY | |

| Positional Accuracy | 0.01 mm |

| Repeatability | ±0.01 mm |

| CNC System | MITSUBISHI E80 |

| SLIDES | |

| X-Axis Stroke | 320 mm |

| Z-Axis Stroke | 175 mm |

| Rapid Transverse X-Axis | 25 mtr/min |

| Rapid Transverse Z-Axis | 20 mtr/min |

| X Axis Servo Motor cap. | 3 Nm |

| Z Axis Servo Motor cap. | 3 Nm |

- 135 Power Chuck with accessories

- Hydraulic Power System with Rotary Cylinder

- Coolant Tank and Chip Collection Tray

- Foot Pedal for Open/Close

- Standard Tool Holders

- Bar Feeder interface

- Coolant System

- Work Lamp

- Collect Chuck Attachment – Ø25 mm

- Parts Collection Box

- Extra Tool Holders

- Hydro Bar Feeder

- Drill Collet Holders

- Spindle Back Stopper

- Bar Puller